Container vessel “Maersk Kowloon” at anchor on the Great Bitter Lake in the Suez Canal. Photo: Tim, CC BY-NC 4.0 via Flickr.

16. Vessel Anchoring

Author: Dr. James A. Fawcett, USC Sea Grant Maritime Policy Specialist/Extension Director (retired)

Media Contact: Leah Shore / lshore@usc.edu / (213)-740-1960

An anchor has two common definitions. Its first meaning is defined as “a heavy device that is attached to a boat or ship by a rope or chain which is dropped into a body of water to secure a boat or ship in place.” Yet, it is also defined as, “a person or thing that provides strength and support”[1] While each of these definitions is useful, they tell only a part of the story about the function of an anchor. For a ship’s anchor, it is only part of the system that secures a ship. Let’s start from the beginning below and explore the details about the importance, purpose, components, and use of a ship’s anchor.

Purpose of a Ship’s Anchor

If we think of a ship as a sort of “bridge” that connects either cargo or people from one location to another, it’s clear that the vessel is a temporary floating intermediate link between those two shorelines. After all, only in the case of Wagner’s opera Der fliegende Holländer (the “Flying Dutchman”) is the ship cursed to sail the seas indefinitely. But, at times, reaching a destination does not mean that the vessel is immediately able to enter the port to be moored to a berth. For many reasons, the vessel may be required to use an offshore anchorage, securing itself in one location for a period of time. In busy harbors, “alongside space”–the common nautical term for a spot along the wharf or where a ship can unload–is often at a premium; ships must wait for their turn to embark or discharge cargo and passengers.

While recreational vessels commonly use small anchors deployable by hand over the side of the boat, merchant ships, because of their size, use a different type of anchor and that will be the focus of this discussion. A ship’s anchor system is relatively simple but consists of a number of elements, each of which is a necessary component of the system. At one end is the anchor itself, which is connected by a stout chain. It is both let go and hauled in by an anchor windlass[2]. so that the chain can be stowed on board in a capacious chain locker below decks. It is a simple system yet with critical importance for the safety of the vessel. Let’s consider the parts of this system.

Types of Anchors

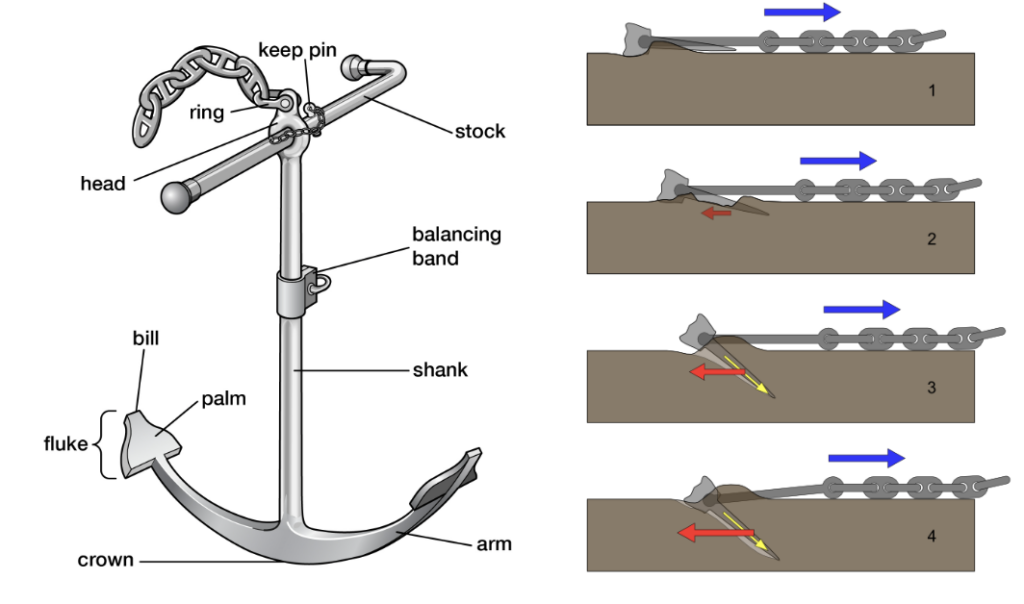

By itself, the anchor is actually the simplest part of a ship’s ground tackle:[3] “the anchors, chains, cables, and other equipment used to secure a ship at anchor.” Today, the most commonly used maritime anchor is the “stockless,” “U.S. Navy,” or “Admiralty” anchor, all of which look essentially similar. They are very different from the stocked anchor, so often depicted in literature, pirate movies, and even symbolically on the U.S. Navy and U.S. Coast Guard uniforms.

The stocked anchor consists of a central shank at the end with two upward curved arms in opposing directions, each of which is furnished with a broad forged fluke acting like a shovel to dig into the bottom. Toward the top of the stock is a long bar attached to the shank but at 90o to the direction of the arms and flukes. Thus, when the anchor reaches the ocean floor, the stock forces the anchor to lie in such a manner with one of the two flukes poised to dig into the ocean floor. (See Figure 1)

Instead of this older design, a stockless anchor, as its name implies, needs no stock to be effective. In fact, it is designed to lie flat on the ocean floor. A much simpler design, it has only one moving part, a bearing or bushing, that attaches the shank to the two flukes. When deployed on the bottom, taking a strain on the anchor chain will cause the two flukes to rotate downward and dig into the underlying bottom. Thus, the bearing between the shank and the flukes acts like an axle, permitting the flukes to engage the bottom. The beauty of the system is its simplicity as well as effectiveness because of its low center of gravity: it wants to dig into the ocean bottom. Stockless anchors can be relatively small (160 kg or ~400 lbs.) to more than 50 tons[4] (the size of the common Caterpillar D9 bulldozer) and this is merely a general idea of their mass. (See Figure 2).

Anchor Chain

Attached to the anchor at one end and to the other end a robust fitting in the ship’s chain locker below decks, the chain is as critical, if not more so, than the anchor itself. If anchors are heavy, the chains that connect them to the ship are equally robust, with single links often weighing hundreds of pounds. An anchor chain used to be measured in “shots” of 15 fathoms (90 feet) joined by a detachable link (painted red) to the next 15-fathom shot. However, merchant ships now often have meters attached to their anchor windlasses, automatically measuring the length of an anchor chain that has been deployed. Generally, the U.S. Navy or merchant ship will carry as much as 1,000 feet of anchor chain or more (per anchor) in its chain locker, depending upon the size of the vessel.[5]

When deployed, it is common to pay out an anchor chain that is 5-7 times the water depth where the vessel is moored. Thus, in 60 feet of water, a ship would deploy 300-420 feet of anchor chain. This length serves two purposes: first, it gives the ship ample room to swing on the chain without placing excess strain on it; second, the weight of the chain and its friction on the ocean floor is the force that actually secures the ship in place, so a large volume of the deployed chain is important.

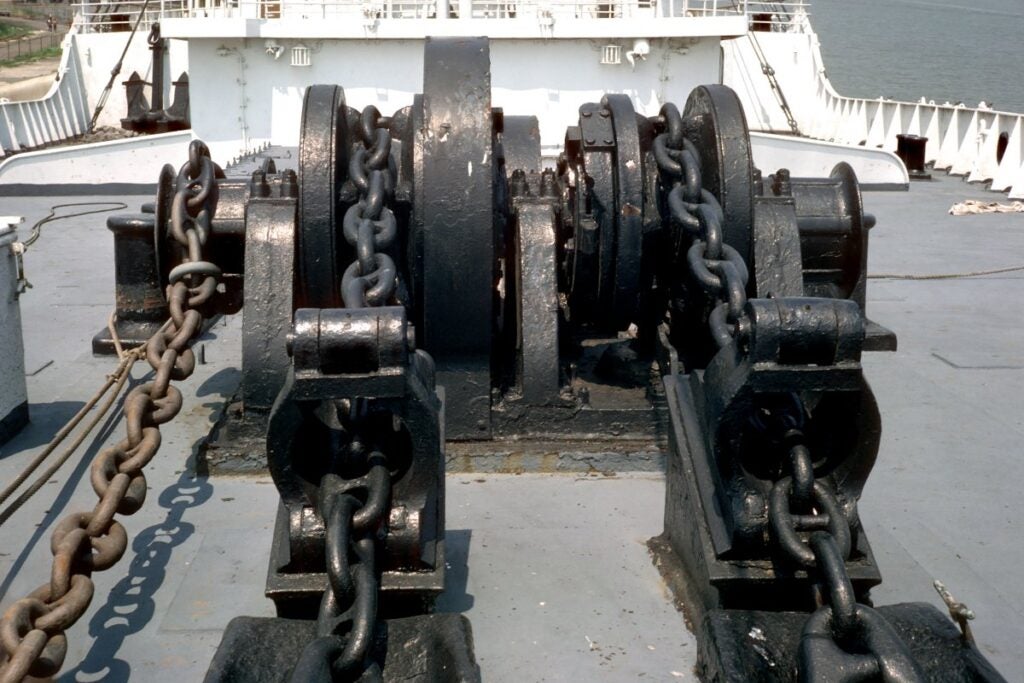

Anchor Windlass

The mass and weight of an anchor and its chain far exceed the capacity of the ship’s crew to manually raise and lower it, so on the foc’sle is a steam, hydraulic, or electric winch that is specifically designed to engage the links of the anchor chain. Equipped with clutches and brakes, the windlass can lower or raise the anchor at any specified rate, including free-running when letting go of the anchor. Upon anchoring, when the appropriate length of chain is discharged, a stopper is installed on the chain preventing further deployment.

The Storage and Use of Anchors

The hawse pipe, a reinforced steel pipe from the foc’sle passing through the ship’s exterior skin allows the anchor chain to attach to the large anchor, which is stowed on the exterior of the ship when not in use. Upon its exterior is further steel reinforcement, creating a cradle in which the anchor is housed, a storage space that is both convenient and out of the way of the ship’s crew working on deck at the foc’sle. Meanwhile, the anchor chain is stowed below decks in the chain locker. Nevertheless, the chain remains connected to the anchor, permitting rapid deployment in an emergency.

Ships carry anchors on both port and starboard sides of the bow, either of which is capable of holding the ship in the anchorage in most cases. Often these two anchors have different lengths of chain depending upon the conditions encountered on the anchorage. Also, it is not uncommon for vessels to deploy both anchors in inclement weather or in an area with a fast current or high winds. In this case, expert seamanship is required to prevent them from becoming “fouled” or tangled.

The Process of Anchoring

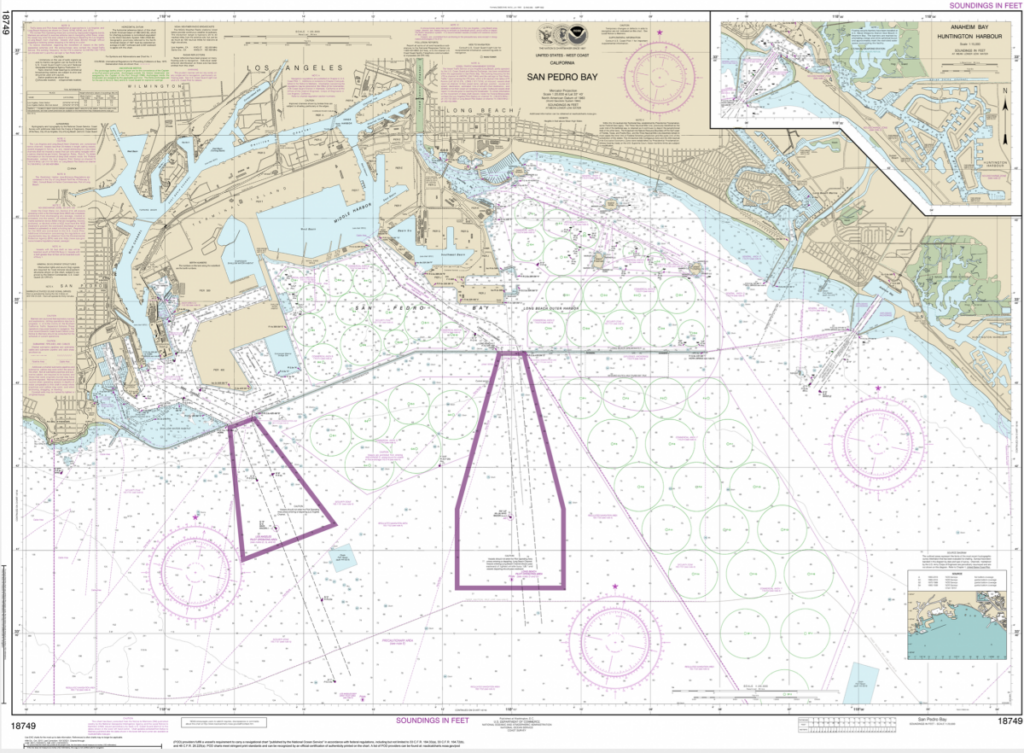

Safe anchorages are defined on nautical charts and are usually designated by numbers and/or letters. Coming into port, the harbormaster, port pilots, and the marine exchange/vessel traffic service (MX/VTS)[6] will instruct vessels on which designated anchorage is to be used. Each anchorage is identified on the relevant nautical chart with a center point surrounded by a circle known as the “anchor swinging circle”. This circle’s diameter is determined by the length of the vessel and displays the area within which the ship, at anchor, is required to reside. There is no “standard” size anchorage because ships are assigned based on the space that they need in order to avoid colliding with adjacent anchored vessels. At the Ports of Los Angeles and Long Beach, the nautical charts define 20 deepwater anchorages inside the long breakwater and 40 outside the breakwater. Additional anchorages are shown on the chart[7] but as CAPT Kipling Louttit, U.S. Coast Guard (ret.) and a leader of the MX/VTS, cautions, some are of limited depth or are reserved for barges with shallow draft.

In normal situations, we will commonly find a few tankers at anchor waiting for their turns at the liquid bulk terminals to offload crude oil for our local refineries, including an offloading buoy in Santa Monica Bay for the Chevron Refinery. However, in our unusual current situation, anchorages are filled with container ships waiting for vacant berths at one of the 13 container terminals in the two ports, terminals that under normal conditions schedule regular arrivals of these vessels with minimal, if any, wait times.

When all available anchorages are occupied—a common occurrence currently—the MX/VTS must find “parking” for them. One alternative is to assign ships to “drift boxes” outside the breakwater, clear of shipping arrival/departure lanes and restricted areas, and in areas defined by navigation coordinates assigned by the MX/VTS. When even those areas become filled the MX/VTS then assigns the waiting vessels to a standby area north of Catalina Island where they may not anchor but must drift under power to stand clear of other drifting vessels.

At anchor, vessels discontinue power to their propulsion engines and continue to operate their auxiliary power plant, which provides electricity to operate normal ship functions including the ground tackle previously described. Under normal conditions, the ship will swing on its anchor and will respond to currents, moving only within the circumscribed anchorage boundaries defined on the nautical chart. At anchor, services to these vessels must be provided by small service vessels bringing provisions, fuel, and other necessities out to them.

The Dangers of a “Dragging Anchor”

Even a stout anchor deployed with an ample amount of anchor chain may not be able to hold a ship in its assigned anchorage under certain weather conditions, most often when the vessel is buffeted by strong winds. The Intergovernmental Maritime Consultative Organization (now the International Maritime Organization) defines “dragging (of an anchor)” as, “an anchor moving over the sea bottom involuntarily because it is no longer preventing the movement of the vessel.”[8] When winds are sufficiently strong, even thousands of pounds of anchor and chain may not prevent the vessel from being pulled away from its anchorage, a condition known as “dragging anchor.” The danger of one of these incidents is that the vessel may collide with an adjacent ship causing damage to one or both. In heavy winds, the ship’s officers are responsible for either visually sighting its position every hour or maintaining a watch on electronic navigation equipment to assess its location within its assigned area.

The ships most vulnerable to “dragging anchor” are those with what mariners refer to as having a large “sail area.” These are vessels with an ample vertical component; in other words, “slab-sided” vessels such as heavily loaded container ships, roll-on, roll-off vehicle carriers, or large passenger vessels where the vessel presents what amounts to a flat “sail” to the wind. Low-lying vessels such as bulk carriers or tankships are less vulnerable because they sit much closer to the water and have low freeboard.

Any vessel that is anchored, irrespective of its configuration, is responsible to its owners, crew, cargo owners, and the public to maintain a vigilant watch when at anchor and in conditions of significant wind. Ultimately, the IMO imposes standards for ship masters to ensure that a vigilant watch is kept when a vessel is at anchor.[9] (See: IMO Circular no. STCW.7/Circ.14 – “Guidance for Masters on Keeping a Safe Anchor Watch.”)

Conclusion

As we now see, the anchor is one in a system of a myriad of components that safely and properly secure vessels; it is not just a simple hook as it appears from afar. The role of the anchor is a critical component to the working of ports such as the POLA and POLB and provides safety for the vessels even among the most uncommon or dangerous sets of conditions.

References

[1] Merriam-Webster. (2003). Merriam-Webster Collegiate Dictionary 11th Ed.

[2] A windlass is a mechanical apparatus for lifting heavyweights. On ships, is it a deck-mounted horizontal drum powered by an attached winch, which is, in turn, powered by steam or, more commonly, by a hydraulic motor. The windlass contains a large wheel, a “chain gypsy,” with indentations that match the size and shape of the anchor chain providing a secure purchase for the chain as it is deployed or recovered. It is located on the foc’sle, the forwardmost upper deck of a ship.

[3] Ibid.

[4] Jinbo Marine. JIS Stockless Anchor Specifications. http://www.chainanchor.com/products/jis-stockless-anchor/. 17 Oct 2021.

[5] The Boatswain’s Mates of USS Nimitz (CVN 68) are making history, as they become the first team of Sailors to remove the anchor and chain of an aircraft carrier rather than contracting the work out to civilians. Fifty-seven links, each weighing 350-pounds, make up just one 90-foot shot of chain that weighs a total of 20,500 pounds. Twelve shots of chain collectively hold a 60,000-pound anchor. Considering the average person weighs less than 200 pounds, it’s safe to say the task of removing Nimitz’ anchors and chain is no small feat. https://allhands.navy.mil/Stories/Display-Story/Article/1839931/pulling-their-weight-anchor-and-chain/.

[6] Personal communication, CAPT J. Kipling Louttit, Executive Director, Marine Exchange and Vessel Traffic Service of Southern California, 19 Oct 2021.

[7] NOAA. Navigation Chart 18749.

[8] IMCO. Resolution A.3so(x): adopted on 14 November 1977. STANDARD MARINE NAVIGATIONAL VOCABULARY. https://wwwcdn.imo.org/localresources/en/KnowledgeCentre/IndexofIMOResolutions/AssemblyDocuments/A.380(10).pdf

[9] IMO. Seafarers’ Training, Certification and Watch Keeping (STCW) Code Chapter VIII Section A-VIII/2. https://www.ukpandi.com/news-and-resources/bulletins/2007/517—0307—keeping-a-safe-anchor-watch—worldwide/