Stacked containers being loaded with cargo at a seaport. Source: Pavel L Photo and Video/Shutterstock.com

2. The Box: An Inside Look at the Shipping Container

Author: Dr. James A. Fawcett, USC Sea Grant Maritime Policy Specialist/Extension Director (retired)

Media Contact: Leah Shore / lshore@usc.edu / (213)-740-1960

Shipping containers, cans, boxes. We’ve all seen them on the road and most of us vaguely understand what they are and what they do, but let’s take a stroll down to the harbor and find out more about these ubiquitous and vital elements of the world’s goods movement system.

A Brief History of the Goods Movement

First a short history: In 1956 Malcolm McLean, owner of a regional trucking company in Winston-Salem, North Carolina had an idea for moving cargo more efficiently. Taking a cue from cargo boxes he observed in WWII to move war materiel, he envisioned moving entire trailers of goods on the deck of ships, saving time and reducing transport costs. His vision grew into Sea-Land Services, Inc. an international container shipping company later purchased by the Danish giant, Maersk Lines and becoming Maersk-SeaLand. At its start, McLean convinced Matson Lines, a Pacific shipper moving cargo between California and Hawaii to successfully use his containers, and with their help, developed a new type of crane to load them on shipboard. Then, by the mid-60s, the Vietnam War called for large volumes of war materiel to be moved overseas efficiently, and his vision of ocean carriage found a receptive audience. What emerged was a system of cargo movement now standard throughout the world.

The Cargo System

The system has four basic component parts: the containers; chassis (base frames of vehicles) designed to turn containers into trailers that can be moved on the highway; rail cars and ships purpose-built for containers; and finally, specialized cranes to load and unload the ships.

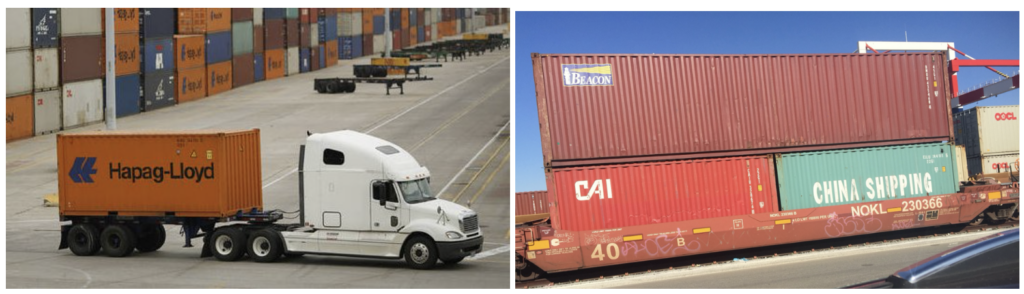

Technically referred to as “intermodal cargo containers,” they are built to standard specifications (ISO 668), generally of steel, in 20-feet or 40-feet lengths, 8’ 6” high and have a gross weight capacity of 30,480 kilograms/67,200 pounds (~30 metric tonnes or about 33 US short tons). By virtue of their modular construction, they can be evenly stacked, especially on ships and trains. The “intermodal” nature of the boxes means that they are equally at home on ships, trains, and on the road when mated to a wheeled chassis. Further, the critical feature is that they are capable of being stacked and secured at their corners to the container both above and below them with steel “cones” that lock the two into place or lock them to a chassis. There can be design variations for use in North America and other unique designs for specific use in Europe, but for international trade, the boxes must be a standard size to be loaded onto ships.

Moving to landside transport, they can be loaded onto flatbed train cars, many of them purpose-built to allow two 40-foot containers to be stacked two-high on a single car. On the road, each container can be fitted onto a specialized wheeled chassis and locked into place. This is what we see on the highway; the chassis is in effect a trailer frame with brakes and tail lights onto which the container is loaded as a passenger. Their versatility is embodied in their name, “intermodal” cargo containers, with the ability to adapt to multiple modes of transport.

The S.S. Ideal X, Malcolm McLean’s first containership, was actually a tankship converted to permit deck loads of trailer vans. There were 58 in that first voyage from Port Elizabeth, New Jersey to Houston, Texas. As the technology and business became more widespread, new ships were built specifically to carry containers. In fact, now container vessels are often described by the number of boxes they can carry with the 20-foot container used as the standard metric, now referred to as a “twenty-foot equivalent unit” or TEU. Containerships have evolved in size from 2,000 TEU vessels in early days to the newest being built at 24,000 TEUs, giant ships over 1,300 feet (400 meters) in length, and as many as 28 containers wide.

Ports have also evolved as the nature of ships and cargo have changed. In addition to deepened ship channels, a new type of gantry crane had to be developed to reach over the vessel, attach to each container and move it from the vessel to the pier to be loaded on a transitional trailer. McLean’s relationship with Matson Lines helped in the design that has now become standard in the industry.

Types of Cargo

What about the cargo itself? The vast majority shipped in containers is dry, general cargo from appliances to clothing to parts, much of which is boxed and packed tightly. In general, seaborne cargo can be described as non-perishable, high volume, low value, or heavy cargo. Thus, flowers or cell phones are not likely to be shipped this way; instead they’ll travel internationally by air.

The container has influenced the dimensions of goods moved by this system as well: the modular space is 8’6” high (9’6” in a “high cube” container), 8’0” wide and either 20- or 40-feet long. As long as the cargo is capable of fitting in that module, it can be shipped. In some cases, even over-height cargo that fits the footprint can be placed as the top container on a deck load. To accommodate various cargoes, containers are made in a wide variety of types: standard dry cargo; refrigerated; flat-rack; tank; open-top; open-side and even “garmentainers” accommodating finished clothing that is hung on racks ready to be moved to retail clothing racks.

A Movement that Brought the World Closer

Our goods movement system has been radically changed by McLean’s invention. Where in 1956, breakbulk (non-containerized) ocean cargo traveled at a cost of more than US$5.00 per ton, its per-ton cost dropped to less than US$0.20 when shipped by container. The evolution in goods movement has affected us worldwide: manufacturers can now afford to move relatively low-value cargo cheaply from one continent to another, and manufacturing is able to seek comparative advantage in labor costs, shifting the geographic locus of employment between countries and continents. Seaports able to host large containerships have prospered, becoming “load centers,” while their smaller competitors have, at times, become moribund. Cities with competitive seaports have become even more cosmopolitan, especially those with efficient landside transportation networks to domestic or receptive adjacent hinterlands. As the goods movement has evolved, the nations of the world have all become a little bit closer. And, all this because of the vision of a truck company owner from North Carolina, Malcolm McLean.