Research Focuses

Research in the Williams Group

Polymer upcycling and fungal metabolism

Chemical valorization is a promising strategy to minimize the environmental hazard of end-of-life plastics; however, many common plastics, like polyethylene used in grocery bags, are devoid of sufficient functional handles to selectively generate products. Other plastics, like polystyrene from disposable cups, can be cleaved selectively but lack sufficient product value relative to the high volume of plastic waste. Biological upcycling of degradation products to valuable secondary metabolites addresses both of these concerns.

Thermoplastic Upcycling. Together with our collaborators in USC’s Mann School of Pharmacy, we demonstrate the conversion of dicarboxylic acids of variable chain length obtained from polyethylene degradation to asperbenzaldehyde and citreoviridin. Genetically modified Aspergillus nidulans enables selection of the desired secondary metabolite.

We also explore the upcycling of polystyrene by conversion to benzoic acid followed by biocatalytic upgrading to ergothioneine, mutilin, and pleuromutilin. Selectivity for the secondary metabolite is again enabled through genetic modification of the biocatalyst. Alternatively, we show success using the benzoic acid from polystyrene upcycling to culture other fungal spores, such as Aspergillus flavus AF36 – an EPA approved biocontrol agent to combat aflatoxins accumulation in agriculture.

We also explore the upcycling of polystyrene by conversion to benzoic acid followed by biocatalytic upgrading to ergothioneine, mutilin, and pleuromutilin. Selectivity for the secondary metabolite is again enabled through genetic modification of the biocatalyst. Alternatively, we show success using the benzoic acid from polystyrene upcycling to culture other fungal spores, such as Aspergillus flavus AF36 – an EPA approved biocontrol agent to combat aflatoxins accumulation in agriculture.

Thermoset Upcycling. Inspired by our success in upcycling polystyrene, we utilize a similar approach to valorize polystyrene-polyester crosslinked composites. We are able to obtain (2Z,4Z,6E)-octa-2,4,6-trienoic acid and clean, high-quality carbon fibers, the latter of which can be remanufactured into high-performance second-generation composites.

Composite recycling – Matrix depolymerizations and fiber recovery

Fiber reinforced polymers (FRPs) are excellent materials that see widespread application due to their high strength-to-weight ratio and chemical/physical resilience. However, the same properties that make FRPs useful during their lifecycle make them incredibly difficult to break apart and valorize at their end-of-life. Together with our collaborators in USC’s MC Gill Composite Center we are exploring a variety of approaches to convert thermoset polymer matrices into feedstock monomers whilst recovering the fiber weaves.

Mechanistic Studies of Depolymerization. We synthesize models of the matrix and study their decomposition under polymer degradation conditions to better understand how to optimize process efficiency and monomer recovery.

Depolymerizing and Remanufacturing Composites. Our team has demonstrated the applicability of our conditions on real-world fiber reinforced composite materials. Monomer precursors are recovered in high purity along with clean, high-quality carbon fibers. We then show applicability of the recovered fibers to remanufacture high-performance second-generation composites.

New Approaches to Hydride Manipulation

We are developing new catalysts and conditions to manipulate hydrides such as various C-H and other X-H bonds. Particularly, we’re interested in coordinatively directed hydride abstraction and new reactions for complex molecule synthesis that feature C-H activation. To achieve these goals, we will employ strategies of catalyst design, thus exploring novel organometallic and coordination chemistry, and target-oriented new organic reaction development.

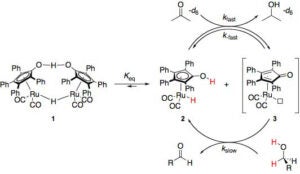

Mechanistic Studies of the Shvo Bifunctional Catalyst. A major emphasis of our group has been to understand thereactivity of organometallic complexes that interact with target substrates through both their metal and ligand.One such complex is the Shvo catalyst, 1.

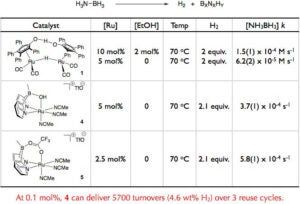

New Catalyst Development. Using the Shvo chemistry as a template, we have designed a new Ru, B scaffold for manipulation of hydride groups. This structural motif gave us the first example of an agnostic bond that is strong enough to displace a ligand from a coordinately saturated metal center, 8. We measured the thermochemistry of this displacement by NMR inversion recovery.

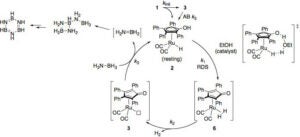

Dehydrogenation of Ammonia Borane. We have applied our catalyst systems to a number of reactions, most notably the dehydrogenation of ammonia borane, a prospective hydrogen storage material. DOI: 10.1021/ja2058154 Our best catalytic systems are air stable, reusable, and can liberate up to 4.6 weight per cent H2 from an ammonia borane slurry.

Mechanistic Elucidation. We are uncovering the mechanistic details of ammonia borane dehydrogenation as part of our ongoing project to understand and utilize hydride transfer reactions that are catalyzed by bifunctional transition metal complexes.

Chemical Probes for Biology and Medicine

Simultaneously and synergistically with our organometallic work, we are devising conceptually novel chemical tools for research and clinical use.Along these lines, we are currently developing the first ultrasound-activated MRI contrast agent.